A Look Behind the Curtain: How We Make Our Book Inspired Soy Candles

Call us Dorothy, because we’re about to pull back the curtain and reveal all our secrets. To better understand our candle making methods, it’s helpful to first understand us as a business. While you’re familiar with our book inspired candles, you may have forgotten about the people and stories behind each scent. Here’s a quick refresher.

Back in the early 2000s, Frostbeard was nothing more than a shadow in Roxie’s mind. In fact, the early 2000s version of Roxie wanted to become a professional potter. And, after a successful Kickstarter campaign, Roxie was able to purchase her first kiln and wheel and began making mugs for all of her supporters and backers in the pursuit of this goal. But while making these mugs was fun, it quickly became apparent to both Tom and Roxie that a more concrete plan was needed if they were going to make a living as artists. So, in early 2012, Frostbeard made its first appearance. Now armed with a logo, name, and vision, Tom and Roxie applied for the rights to the Frostbeard name and subsequent business license.

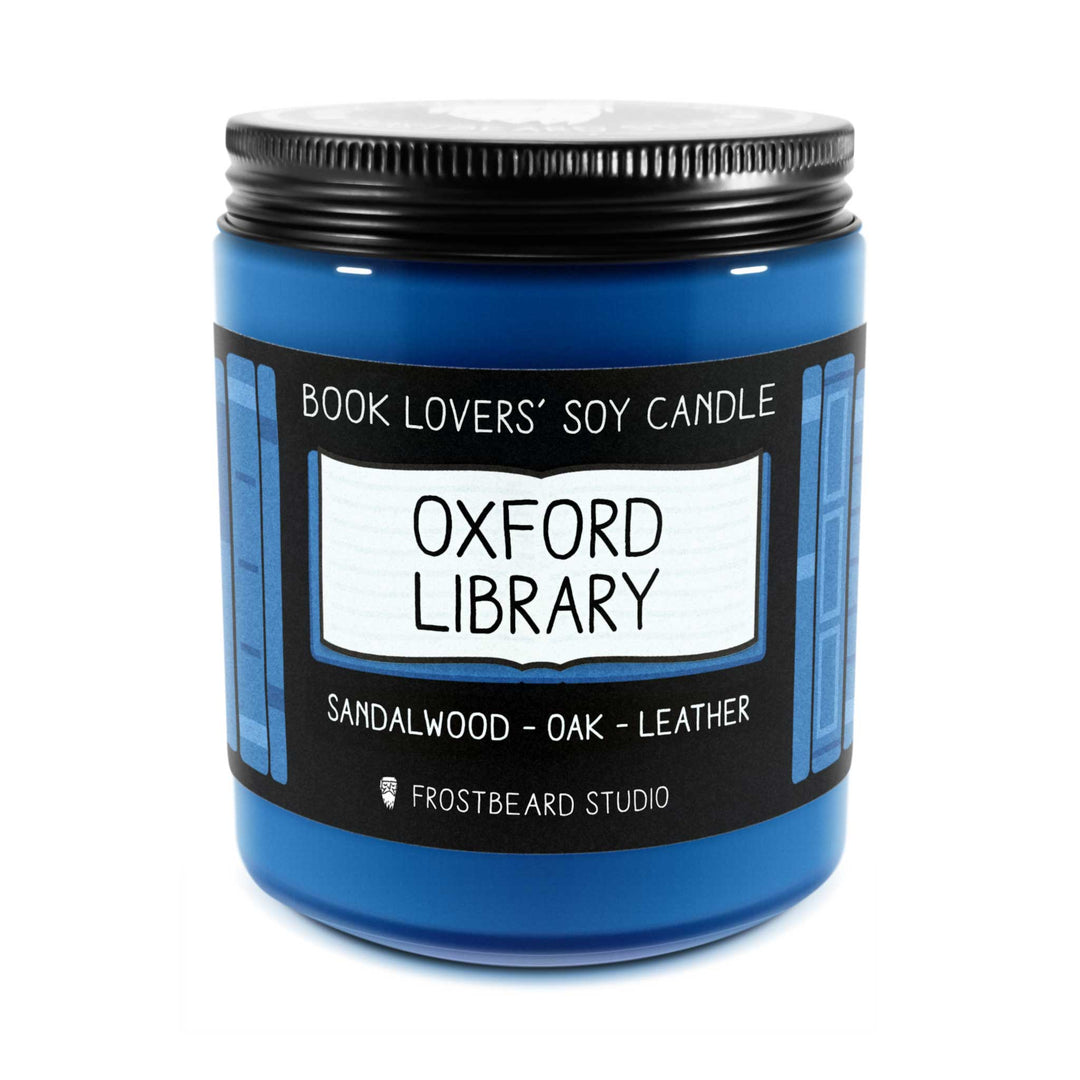

Now, you’re probably wondering where candles come into this story. Well, just wait, we’re nearly there. Ok, so Frostbeard is now an official business selling mostly ceramic goods at local art fairs and a little bit online. And then one day, Roxie’s mom recommended she add candles to her Etsy store. These first candles were originally made on the stove top and were poured in mason jars and then finished with a handwritten label. And what candles did Roxie decide to make in her mother’s kitchen? Book themed ones of course! After having spent hours looking for a library scented candle online, Roxie became fed up with the lack of literary scents available and made her very first book inspired candle; Oxford Library. And the rest, as they say, was history. Roxie and Tom married in fall 2012, and they began working side by side the next spring. Tom redesigned the Frostbeard candle labels and brought a more design-y touch to their online selling platform, and the pair worked on growing the business. Ok, so that's the who, now let's cover the what.

Our Candle Making Process

For us, it all starts with sourcing local ingredients. We take pride in gathering the soy wax used to make our candles from all around the Midwest. And once we secure our wax, it’s time to get cooking. Or should we say melting?

When it comes to melting our wax, we’ve gone through a couple of rounds of refining and expanding our process to find the perfect setup to meet our needs. As mentioned above, Roxie originally melted wax in a large pot on her mom’s stove. This process led to quite a few problems as it was tricky to keep the wax at a consistent temperature, and pouring the wax into smaller containers was super messy.

We eventually upgraded to a 40 qt wax melter that we named Frodo. Because obviously. We acquired Frodo through our second fundraising campaign, the very same one that helped us move our setup from inside Roxie’s mom’s house to our small apartment in Minneapolis. This system worked alright... (cramped, but we managed) until we were featured in a BuzzFeed gift list. This happened right before Christmas and it changed our lives. Due to the new rush of Frostbeard fans prompted by the article, we ended up purchasing 650 pounds of wax, and had to shut down ordering on our site because we simply were unable to make enough candles to meet this new found demand.

After the Christmas rush died down, we worked continuously to turn our sudden stardom into a sustainable business, and we’re proud to say, years later, that we made that happen through hard work and determination. The first thing we did in January was move into our first actual studio space in the arts district of Northeast Minneapolis. We also hired our first studio assistant and took the plunge into learning how to be both professional makers and business owners.

We added another, even bigger 80 qt wax melter (named Gandalf, of course). This new behemoth can turn out 400 candles a day, and we love it! We melt our wax at 170 degrees until it liquifies, at which point, we use the spigot on the front of the melter to distribute smaller batches of wax into waiting stainless steel pouring pitchers. The beauty of this larger wax melter is that it will keep the wax at our desired temp for as long as we need without letting it solidify again. This lets us continue to create small, consistent batches of candles by hand.

Coloring, Scenting, and Pouring our Candles

Once the wax has been transferred to our pouring pitchers, we add in chips of different colored wax dyes to reach the desired look we’re going for. We come up with a special recipe for each candle so that we can then recreate them as consistently and easily as possible. Our colors are all tested and workshopped before we start production so that we have ample time to create the perfect hue to accompany our signature scents.

Once the dye has reached our desired color, it’s time to add some hand selected fragrances! If you ever come to visit us in our shop, one of the first things you’ll notice is our wall of fragrances. With everything from dragon’s blood to freshly minted paper, we have a veritable library of scents at our disposal when it comes to crafting new book inspired candles.

Luckily for us, Roxie has an above average sense of smell. With her super sniffer, Roxie is able to deftly combine multiple scents together to produce a finished product that elicits the exact feelings that one experiences when enjoying the book which was used to inspire the scent. Some such scent combinations include fireplace, cedarwood, and lemon, which when blended together create our Headmaster’s Library candle.

After the scented fragrance oils have been added to our wax, it’s time to pour! But before we add any wax to either our glass jars or aluminum tins we prep the candle vessels by inserting a lead-free cotton wick. Once that’s all set, we carefully pour each individual candle by hand and then use a wick bar to hold the wicks in place as the candles cool. We then let our candles set overnight at room temperature. Once dry, the wicks are trimmed to ¼ inch, the labels are attached and then they’re ready to be sent to their new homes!

The Scents That Just Keep on Giving

We spend our days basking in the magnificent scent of our favorite literary worlds, and we wouldn’t have it any other way! In 2018, we’re hoping to keep our candle making services going strong while setting aside more time to focus on some of our other loves, such as illustrating and pottery. And with an awesome team, we’ve been able to create new and unique book scents such as the all-new Pemberley Gardens candle as well as some exciting bookish merch! When it comes to how to make soy candles, there are many ways to go about it. We’re by no means experts, but these are the methods that have gotten us this far, and that will keep us going in the future.